Key Highlights

- In bulk dry fruits trade, the price comes later. First bulk dry fruits buyers check whether the lot is safe and stable enough to ship without problems.

- A quick look at colour, size, and broken pieces usually tells half the story before any test even starts.

- Moisture is something nobody takes lightly. Even a small excess can spoil the cargo during transit.

- Size grading matters more than people think — bigger and more uniform kernels simply sell better and fetch stronger rates.

- Most bulk dry fruit importers still rely on simple habits like smelling, tasting, and pulling samples from different bags. Old methods, but they work.

- For paperwork, nuts usually ship under HS 0802, raisins under 0806, and other dried fruits under 0813 — getting the code right early saves a lot of back-and-forth at customs.

Introduction:

Bulk dry fruit buying looks simple from the outside. A few containers of almonds, some cashews, maybe raisins or pistachios — load them and ship. But anyone who has actually handled these deals knows it’s never that casual. One weak lot, a little excess moisture, or poor grading can quietly turn into claims, rejections, and losses after the cargo lands. That’s why experienced buyers slow things down at the inspection stage. They would rather spend an extra hour checking than spend months arguing later. In this trade, caution isn’t overthinking — it’s survival.

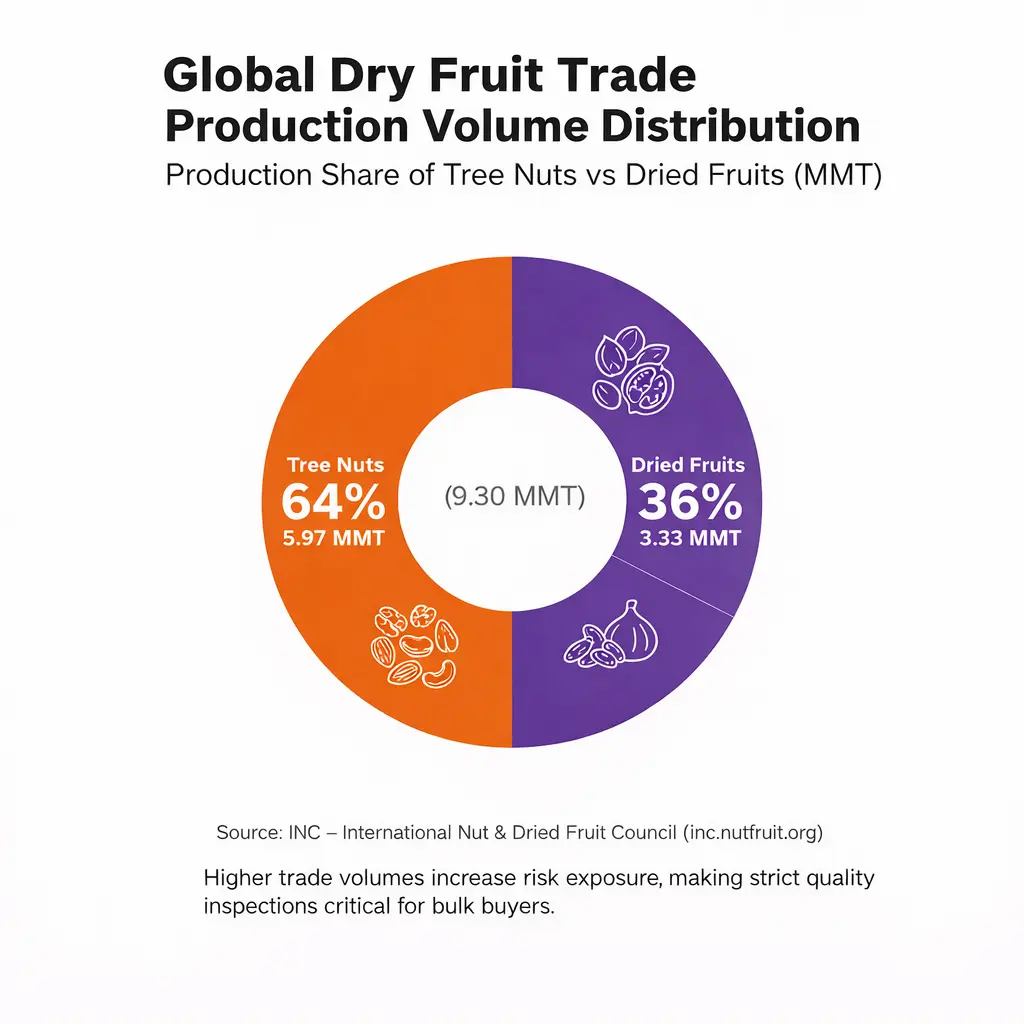

Out of roughly 9.3 million tonnes, tree nuts take the larger share. Dried fruits follow. Bigger volumes usually mean bigger risk, so buyers tend to be extra careful with inspections and handling.

The First Check Is Always Visual

Before instruments, before lab tests, buyers usually start with their eyes. A simple handful of products often says more than a long specification sheet. Colour, shine, and uniformity immediately tell you how the lot has been processed and stored. If the product looks tired or uneven, something probably went wrong upstream.

Buyers typically look for:

- uniform size and grading

- natural colour, not dull or patchy

- minimal broken or shrivelled pieces

- absence of dust, stones, or foreign matter

It’s basic, almost old-school, but surprisingly reliable. Years in the bulk dry fruits trade train the eye faster than any machine.

Moisture Is the Silent Risk Nobody Ignores

Moisture is one thing buyers usually check first, especially with dry fruits.

The product is supposed to stay dry and stable, and moisture is its biggest enemy. It won't be a hyperbole to say that even a tiniest increase can cause issues during transit. Containers are at sea for weeks, and there is no doubt in saying that inside can get humid depending on the weather and storage conditions.

Problems like mould or fungus can start developing once moisture builds up. And it is frightening to imagine that by the time the shipment reaches the destination, there isn’t much scope to fix it. Which means that most of the loss has already happened.

So moisture checks are taken seriously:

- handheld moisture meter readings

- random bag testing, not just one sample

- lab verification for large orders

- rejection of lots above safe limits

In short, “dry” has to truly mean dry. Otherwise the risk simply isn’t worth it.

Size Grading Directly Affects Pricing

Most new buyers don’t pay much attention to size in the beginning. It feels like a small detail. But after a couple of shipments, they usually realise it matters more than they thought.

In nuts like almonds, cashews, or pistachios, size directly affects how the lot is priced. Bigger, uniform kernels generally move faster and sell better. Mixed sizes or too many broken pieces? Those tend to get negotiated down pretty quickly.

Retailers and food brands aren’t chasing perfection — they just want packs to look consistent. Nobody wants one packet full of large pieces and the next looking uneven. In this business, uniformity simply makes life easier for everyone.

So buyers carefully check:

- kernel count per ounce or kilogram

- uniformity across the shipment

- percentage of splits and broken pieces

- overall grading accuracy

Because inconsistent sizing slows packing lines and creates complaints downstream. And nobody wants that.

Smell and Taste Still Matter More Than Fancy Tools

For all the modern testing equipment available today, some of the most reliable checks are still surprisingly simple. Dry fruit importers open a sack, take a handful, smell it, sometimes even taste a few pieces. It sounds informal, but it works. Rancidity, staleness, or poor storage usually shows up first through smell.

These quick sensory checks often include:

- checking for rancid or oily odour

- tasting for freshness and crunch

- feeling texture for softness or dampness

- spotting early signs of infestation

It’s instinct built over years. A seasoned dry fruit trader can often sense a problem in seconds.

Random Sampling Keeps Everyone Honest

One common mistake is judging a lot from a single bag. Experienced importers rarely do that. They sample separately and randomly from different stack points — top, middle, and bottom. Because sometimes the top layer looks perfect while lower bags tell a different story.

So the routine usually involves:

- opening multiple bags across the lot

- checking samples from different pallet rows

- comparing consistency between bags

- rejecting uneven sections

It’s not about distrust. It’s simply risk control. Better to find issues early than after the container sails.

Documentation and HS Codes Matter Just as Much

Even the best quality product won’t move if the paperwork is wrong. Classification, compliance, and food safety documents are part of the same quality process. Buyers double-check these details carefully because customs delays can cost more than minor price differences.

Common classifications include:

- HS 0802 – almonds, cashews, pistachios, walnuts and other nuts

- HS 0806 – raisins and dried grapes

- HS 0813 – other dried fruits

Along with that, top dry fruit buyers usually verify phytosanitary certificates, fumigation records, and aflatoxin or pesticide limits, especially for EU-bound shipments. Small errors here can stall cargo for weeks.

Final Thoughts

At the end of the day, dry fruit quality checks aren’t complicated or dramatic. They’re just thorough. Look closely, test moisture, verify size, smell the product, review documents, then sample again. Nothing fancy, just disciplined habits built over time. That’s how seasoned dry fruit buyers protect their margins and sleep better at night.

Because once a container is on the water, there’s no turning back. And in bulk dry fruit trade, prevention is always cheaper than correction.

.webp)