Key Highlights

- Coffee grading for exports is less about “premium vs low quality” and more about consistency — buyers care about how the beans behave in roasting, grinding, and brewing, not just how they look.

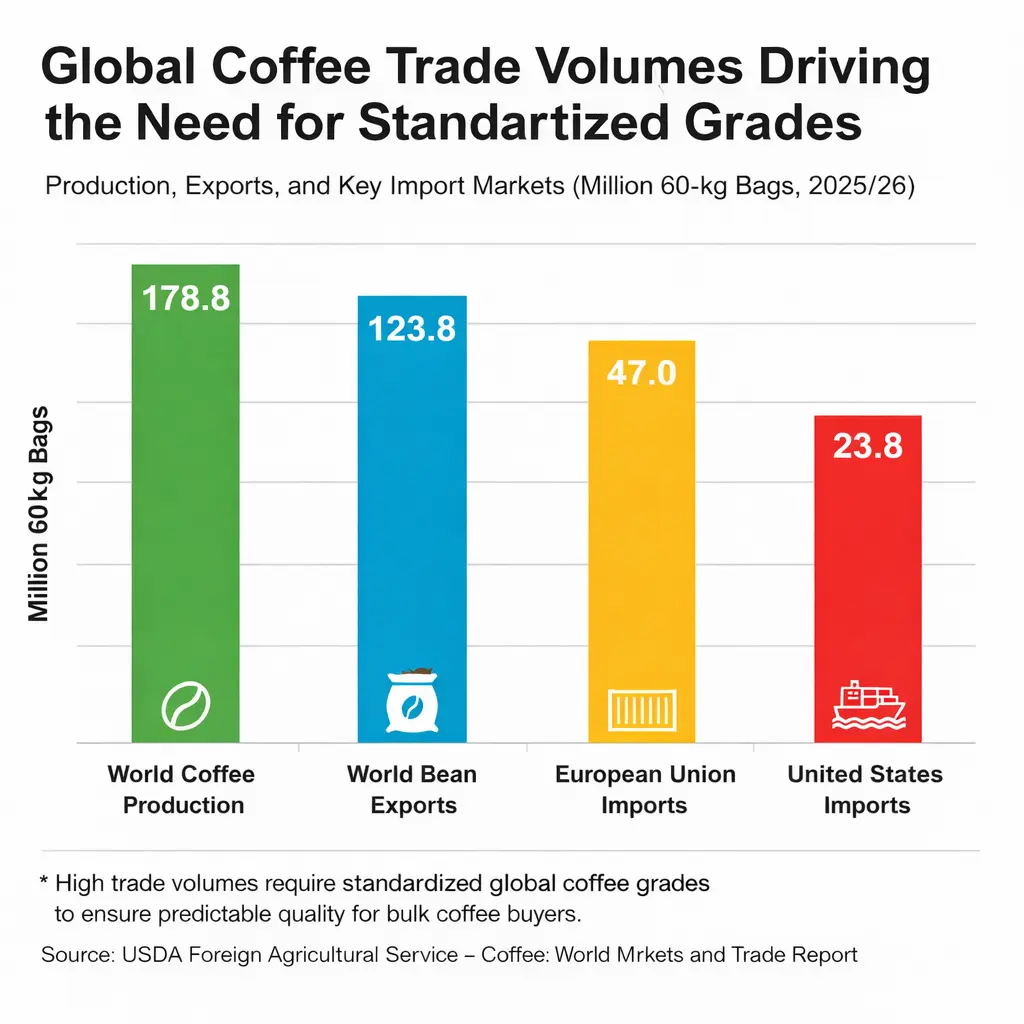

- With global production touching around 178.8 million bags and exports near 123.8 million bags, standardized grades are what keep international trade running smoothly.

- Major importers like the European Union (≈46 million bags) and the United States (≈23–26 million bags) depend on predictable specs and uniform lots, which makes grading non-negotiable.

- Export decisions are based on screen size, defects count, moisture, and cupping scores — a mix of machines and human tasting tables working side by side.

- HS classifications matter at shipment stage: 090111/090112 (green coffee), 090121/090122 (roasted), and 210111/210112 (soluble coffee) — paperwork mistakes can delay cargo faster than any price dispute.

- At the end of the day, the goal is simple: deliver the same cup profile, shipment after shipment — because in bulk coffee trade, surprises cost money.

Introduction:

Spend a day inside a coffee export warehouse and you’ll notice something interesting. Nobody talks about “premium” or “ordinary” the way café menus do. There’s no drama, no marketing language. Just sacks, screens, sample trays, and people quietly doing their checks. Yet those quiet checks decide whether a lot ends up with a European roaster, an American supermarket brand, or a bulk soluble coffee plant somewhere in Southeast Asia.

That’s the reality of export grading. It’s less romance, more routine. And in a global coffee trade where the world now produces close to 178.8 million bags and ships out roughly 123.8 million bags annually, routine is exactly what keeps the system from falling apart .

At that scale, bulk coffee buyers don’t want surprises. They want predictability. Different coffee grades are simply how the industry delivers that.

Coffee Grade Is About Function, Not Prestige

The first misconception many newcomers carry is that different coffee grades mean “good versus bad.” In export trade, it rarely works that way. Grade mostly tells a buyer how the coffee will behave — how evenly it will roast, how fast it will extract, how consistent it will taste across thousands of cups.

A specialty roaster and a soluble manufacturer are solving two completely different problems. So naturally, they ask for different grades. One wants character and complexity. The other wants uniformity and yield.

It’s not about ego. It’s about purpose.

At a basic level, exporters classify coffee by:

- Screen size (bean size uniformity)

- Defect count

- Moisture level

- Density and appearance

- Cup quality through tasting

Get these right, and half the deal is already done.

The Sorting Floor: Where Size Gets Decided

Most grading starts with something surprisingly simple — sieves and screens. After hulling and cleaning, beans pass through graded meshes that separate them by size. Larger beans stay on top, smaller ones fall through. It’s almost mechanical, like sand through a filter.

Nothing fancy. Just gravity doing its job.

But size matters more than people think. Uniform beans roast evenly. Mixed sizes roast unevenly, which can throw off flavor. For commercial bulk coffee buyers running huge roasting drums, uneven roasting is a headache they don’t want.

So exporters separate lots carefully and label them accordingly.

Typical screen classifications include:

- Large screens for premium whole-bean retail

- Medium screens for balanced commercial roasting

- Smaller grades for blends or soluble use

It’s one of those quiet steps that nobody markets, yet everybody depends on.

Defects: The Part Bulk Coffee Buyers Watch Closely

If screen size is about appearance, defect counting is about risk control.

Before export, trained graders spread samples on a table and manually pick out broken, blackened, insect-damaged, or fermented beans. It’s slow, meticulous work. Old-school, almost. But it still matters.

Because defects don’t just look bad — they taste bad.

Too many, and the cup gets muddy or bitter. For a buyer importing containers worth thousands of dollars, that’s not a small issue. That’s a contract dispute waiting to happen.

So exporters follow tight tolerances.

Common checks include:

- Black or sour beans

- Broken pieces

- Foreign matter (stones, husk, sticks)

- Mold or insect damage

Less guesswork, fewer headaches later. Simple logic.

Cupping: Where Human Judgment Takes Over

After all the mechanical steps, grading still comes down to something very human — tasting.

Cupping tables are where numbers meet reality. Samples are roasted lightly, ground, brewed, and slurped (yes, loudly — that’s part of the technique). Tasters look for aroma, acidity, body, and consistency.

It’s half science, half instinct built over years.

Because here’s the truth: you can’t measure flavor with a ruler.

Bulk coffee buyers often specify minimum cup profiles. Exporters taste repeatedly to ensure the shipment matches expectations. Nobody wants the first container to taste great and the second one to taste flat. Consistency is everything.

In the global coffee trade, “same as last shipment” is the sweetest compliment.

Why Standardization Matters More Than Ever

Zoom out a bit and you’ll see why all this discipline exists.

Coffee today isn’t a small artisanal trade. It’s massive. The European Union alone imports over 46 million bags, and the United States more than 23 million bags annually . With volumes like that, even small quality variations multiply fast.

Add rising consumption and tightening stocks, and the market gets even more sensitive. Global ending stocks are projected near 20 million bags, which has helped push prices sharply higher in recent years .

When prices rise, bulk coffee importers become stricter. Every shipment has to justify its value.

That’s when grading stops being paperwork and starts being insurance.

The Trade Basics Bulk Coffee Importers Still Care About

Beyond taste and size, there are a few boring-but-essential details that every exporter double-checks before shipment. Miss these, and even perfect coffee won’t save you.

Typical export checkpoints include:

- Moisture levels within safe storage limits

- Clean, uniform bagging

- Correct weight conversion

- Proper HS codes (090111 for green coffee, 090121 for roasted, 210111 for soluble extracts)

coffee - Pre-shipment samples approved by the buyer

Not glamorous. But in global trade, paperwork can delay a container faster