Which TMT Grade is Right for Your Project? Fe 500, Fe 550, or Fe 600?

Key Highlights

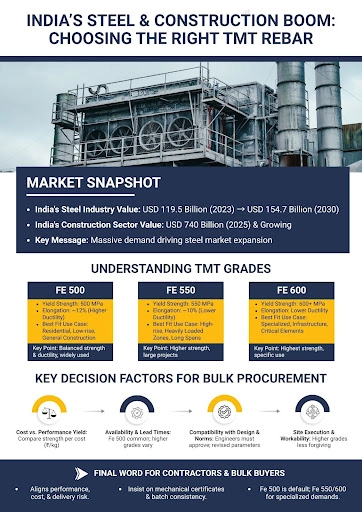

- India's steel market is poised for significant expansion, driven by construction demand

- Fe 500, Fe 550, and Fe 600 grades differ in yield strength, ductility, and cost — key tradeoffs for large projects.

- For bulk TMT steel supplier relationships, alignment of grade, cost, and project risk is essential.

- The choice of grade must align with structural demands, site conditions, and long-term durability.

India's Steel & Construction Backdrop

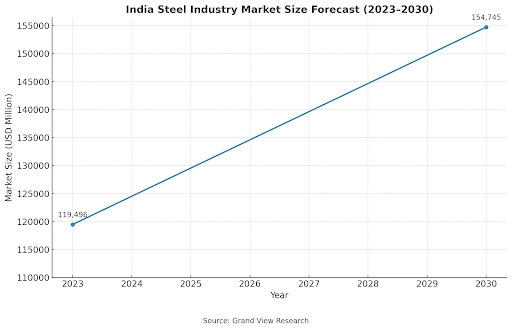

India's steel industry is a vibrant and prospering industry. It is a foundational part of the infrastructure and real estate expansion. The enormous size of this industry can be estimated from the fact that it was valued at USD 119,496 million in 2023, and is forecast to grow to approximately USD 154,745 million by 2030 at a 3.8 % CAGR.

Meanwhile, India's construction sector is estimated at USD 740.08 billion in 2025, with expectations of robust growth toward 2030. In this setting, construction companies routinely Buy TMT bars in bulk for high volume projects. The decision on TMT bar grade (Fe 500 vs Fe 550 vs Fe 600) translates into significant cost, performance, and risk implications across large portfolio contracts.

Understanding Fe 500, Fe 550, Fe 600 Grades

Mechanical & Structural Differences

- Fe 500: This grade ensures a minimum yield strength of 500 MPa and a characteristic tensile strength (ultimate) around 545 MPa. Many Fe 500 bars maintain elongation in the range of 12 %. It offers a balanced blend of strength and ductility, making it widely used in general construction.

- Fe 550: This higher grade raises the yield threshold to 550 MPa and tensile strength ~585 MPa. It tends to have slightly lower elongation (e.g. ~10 %) but stronger load resistance per unit bar.

- Fe 600: While rarer in domestic markets, Fe 600 is sometimes specified for heavy industrial, high-rise, or highly stressed structural elements. It provides even higher strength margins, at the cost of increased material stiffness and possibly reduced ductility.

When choosing, construction firms must weigh strength per kg vs workability and ductility under stress.

Ductility, Weldability & Site Performance

Higher grades (Fe 550 and Fe 600) tend to use more controlled alloying and reduced carbon content to maintain weldability and bend capacity. But the tradeoff is that ductility (capacity to absorb deformation before failure) can be reduced. In seismic-prone or dynamic load zones, this matters. Many Fe 550D variants introduce “D” for ductility enhancements, giving improved elongation despite the higher strength.(ARS Group)

Fe 500 grades, being more ductile, may better accommodate micro-movements, temperature cycles, and less-than-ideal site bending or cutting conditions.

Which Grade Suits Which Project Type?

Residential, Low-rise & Medium Commercial Works

For typical homes, offices, schools, and small-to-moderate commercial buildings, Fe 500 continues to dominate. It balances cost, ease of handling, and structural adequacy, especially under standard load profiles. Many Indian contractors and developers prefer Fe 500 as their default construction TMT bars.

High-rise, Long Spans & Heavily Loaded Elements

Projects involving high floor-counts, large column loads, long span beams, or prestressed elements may benefit from Fe 550 or Fe 600. The higher strength allows reduction in steel cross-section or margin buffers. In such cases, TMT bars for construction projects with Fe 550/600 can optimize steel usage per ton of load.

However, one must ensure that all structural design, detailing, and safety margins (bending, welding, anchorage) are adjusted to suit higher grades.

Critical Infrastructure, Bridges, Dams & Heavy Civil Work

In infrastructure or heavy industry projects, there is a case for Fe 600 (or hybrid composites) in particularly stressed components. But the costs, specialized handling, and availability limits often restrain widespread adoption in typical building projects.

Decision Factors in Domestic Bulk Procurement

Cost per Ton vs Performance Yield

A key metric is cost per effective strength unit (MPa per kg). Bulk TMT steel supplier quotes must be compared not just on ₹/kg but on strength yield per cost. Higher grade bars fetch premium prices; unless the incremental strength yields material savings, sticking with Fe 500 may be more economical.

Availability, Lead Times & Inventory Risk

Fe 500 is more ubiquitously produced and stocked. Fe 550 or Fe 600 may involve lead time risk or sourcing from fewer mills. A large contractor ordering 1,000 MT of TMT bars in bulk must ensure supplier capacity and consistency.

Compatibility with Design & Detailing Norms

Designers and structural engineers must approve usage. The bending, lap length, anchorage length, and detailing vary subtly with grade. Changing from Fe 500 to Fe 550 may require revised parameters in reinforcement drawings.

Site Execution, Bending & Welding Capacity

At site level, fabricators, bend-shops, welders must handle the grade appropriately. Higher strength bars are less forgiving to over-bending or cold works. If the site lacks skilled handling, Fe 500 gives more margin for error.

Quick-Reference Comparison

| Grade | Yield Strength (MPa) | Typical Elongation | Typical Elongation |

|---|---|---|---|

| Fe 500 | 500 | ~12 % (or more) | Standard buildings, residential, low-rise |

| Fe 550 | 550 | ~10 % (or lower) | High-rise, heavier load zones |

| Fe 600 | 600 (or higher) | Lower ductility | Specialized, infrastructure, critical elements |

Final Word for Contractors & Bulk Buyers

For domestic construction firms and contractors, the selection between Fe 500, Fe 550 or Fe 600 cannot be a generic push toward “higher is better.” It must be conditioned on structural demands, site capabilities, supply chain reliability, and cost yields.

When you plan to buy TMT Saria or order from a bulk TMT steel supplier, insist on mechanical certificates, bend/weld trials, and batch consistency. If a high-rise or heavy structural element calls for Fe 550 or Fe 600, ensure your designer, supplier and site capably support that specification.

In many mainstream building contracts, Fe 500 remains the default and safe choice. But forward-looking projects with heavier demands or value optimization may rightly adopt Fe 550 (or Fe 600 where justified). The right grade is the one that aligns performance, cost, and delivery risk — not merely the highest spec on paper.

.webp)